Machinery and equipment

Industrial assisted robotic arm

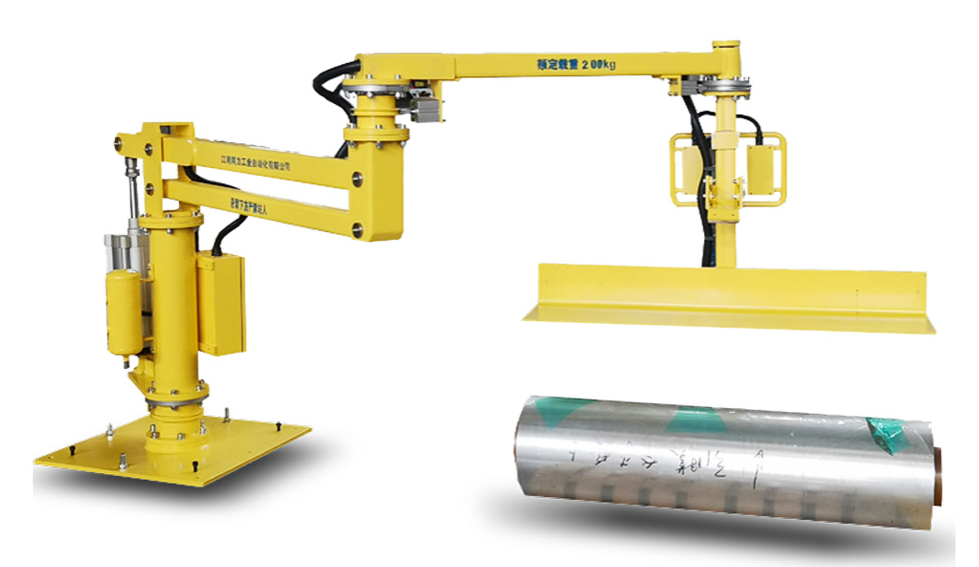

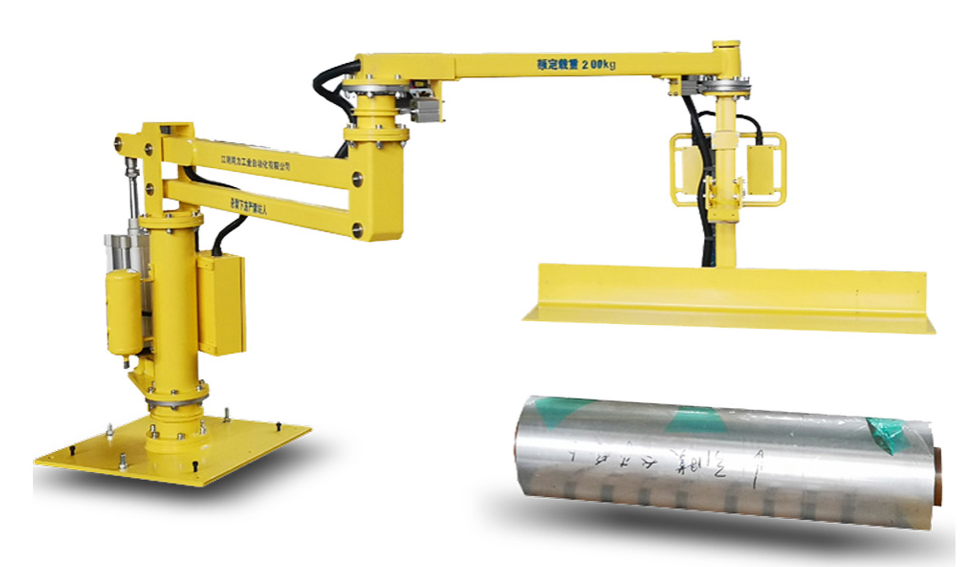

- Product description: Industrial assisted robotic arm

The handling robot arm imitates human hand movements, completing the actions of grabbing and moving goods, which can effectively reduce labor costs and reward labor costs. Applied in various industries such as automobile manufacturing, metallurgical casting, metal processing, mechanical manufacturing, paper processing, printing and packaging, food and beverage, tobacco and alcohol, clothing fabrics, home appliances, electronic communication, power transmission and distribution, military research, aviation and shipbuilding, chemical petroleum, building materials, ceramic bathroom, wood processing, furniture, warehousing and logistics centers.

Easy and fast operation: Follow the traction of the operator to complete the lifting, pushing, rolling, tilting and other movements of the workpiece, easily move the workpiece, and assist in assembling the workpiece.

Suspension without impact force and rebound force: It can ensure flexible docking during product assembly, avoiding the impact and rebound force of ordinary lifting equipment during operation.

Accurate positioning: In a zero gravity suspension state, ensuring precise positioning during product docking with random movement.

Energy saving: The entire machine does not require a power source, only a pipeline connected to a 0.6MPA gas source is needed to complete all work.

Safety: A pneumatic control system composed of carefully selected imported high-quality pneumatic components, equipped with safety mechanisms such as air source accidental interruption protection, misoperation protection, low pressure alarm, safety follow-up butterfly brake, buffer air storage tank, etc., to maximize the safety of operation and workpiece.

Categories

Latest News

Contact Us

Contact: Gloria

Phone: +8613681981380

Tel: +86 021-64556477

Add: Room 312, Factory Building, No. 338 Shuangbai Road, Minhang District, Shanghai