Mechanical robot

UCANI industrial truss CNC robot arm

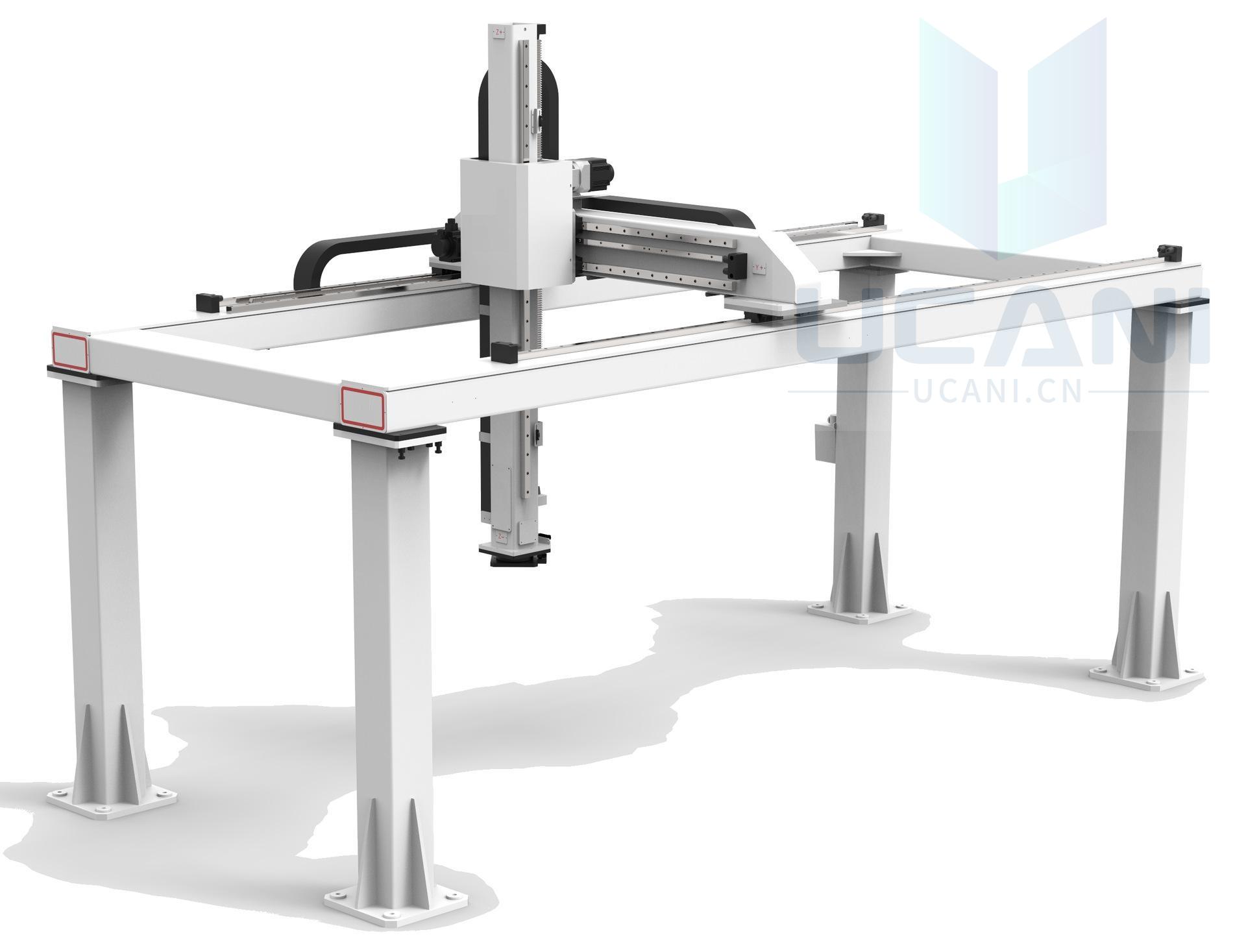

- Product description: UCANI industrial truss CNC robot arm

UCANI CNC truss robotic arms are a substitute for manual operations, but of course they are robotic arms and look slightly different from robots. The focus of lathe robotic arms is on robotic arms, so in the future, CNC truss robotic arms will become more intelligent! Of course, we are discussing functionality here.

From handicraft factories to mechanical power production, we look back at the history of global industrial development. Now, relying on technology determines victory and survival. Companies that benefit from cheap labor now face a bottleneck and expense in terms of labor. In the development of enterprises, you only need to change your mindset, focus on the future, keep up with the times, and prepare for the great development of the enterprise automation industry.

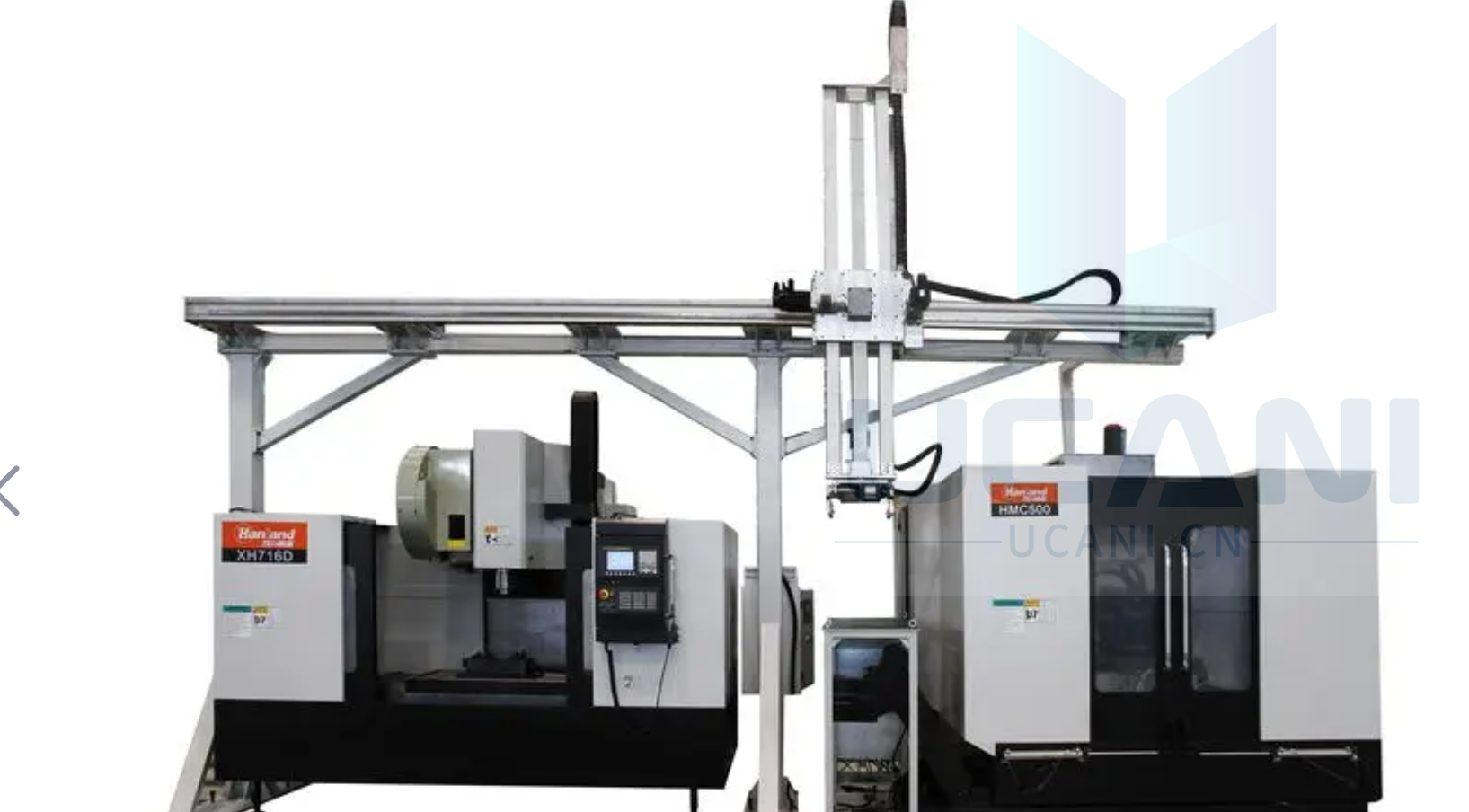

Nowadays, domestically produced industrial robot manipulators are widely used in automated production lines. The development and production of CNC truss manipulators have become a rapidly developing new technology in the high-tech field, and the organic combination of mechanization and automation can be better achieved between manipulators and manufacturing manipulators. CNC robotic arms are mainly used in the field of CNC machining to reduce labor intensity and improve working conditions. Gradually, the application of truss type CNC machine tool manipulators, CNC manipulators, loading and unloading manipulators, truss manipulators, and multi line manipulators is becoming increasingly widespread.

In addition, the CNC truss manipulator not only brings the latest production technology used by the manipulator to the production of CNC enterprises, but also the latest management mode thereafter, making the enterprise more active Long live and market competitiveness. Many companies have increased their product variety from less than 12 in the past to dozens now, and the number of boutiques has also significantly increased compared to before, which has had a significant impact on market competitiveness and survival ability.

The CNC truss manipulator is an intelligent alternative to manual loading and unloading, which can achieve automation of the machining process. Mechanical processing is a tedious and arduous task for humans. The CNC truss manipulator can greatly improve work efficiency. Previously, three workers were required to work simultaneously, but now one person is needed to monitor and execute robot operations, resulting in faster work speeds.

Industrial robots are the gateway to the new industrial revolution and are becoming an important growth point, affecting manufacturing formats. Its research and development, manufacturing, and application have become important indicators for measuring the level of national innovation and manufacturing. As a type of industrial robot, the application of CNC truss manipulator is becoming increasingly widespread. For cities with good robotics and equipment manufacturing industries, developing the robotics industry has many advantages.

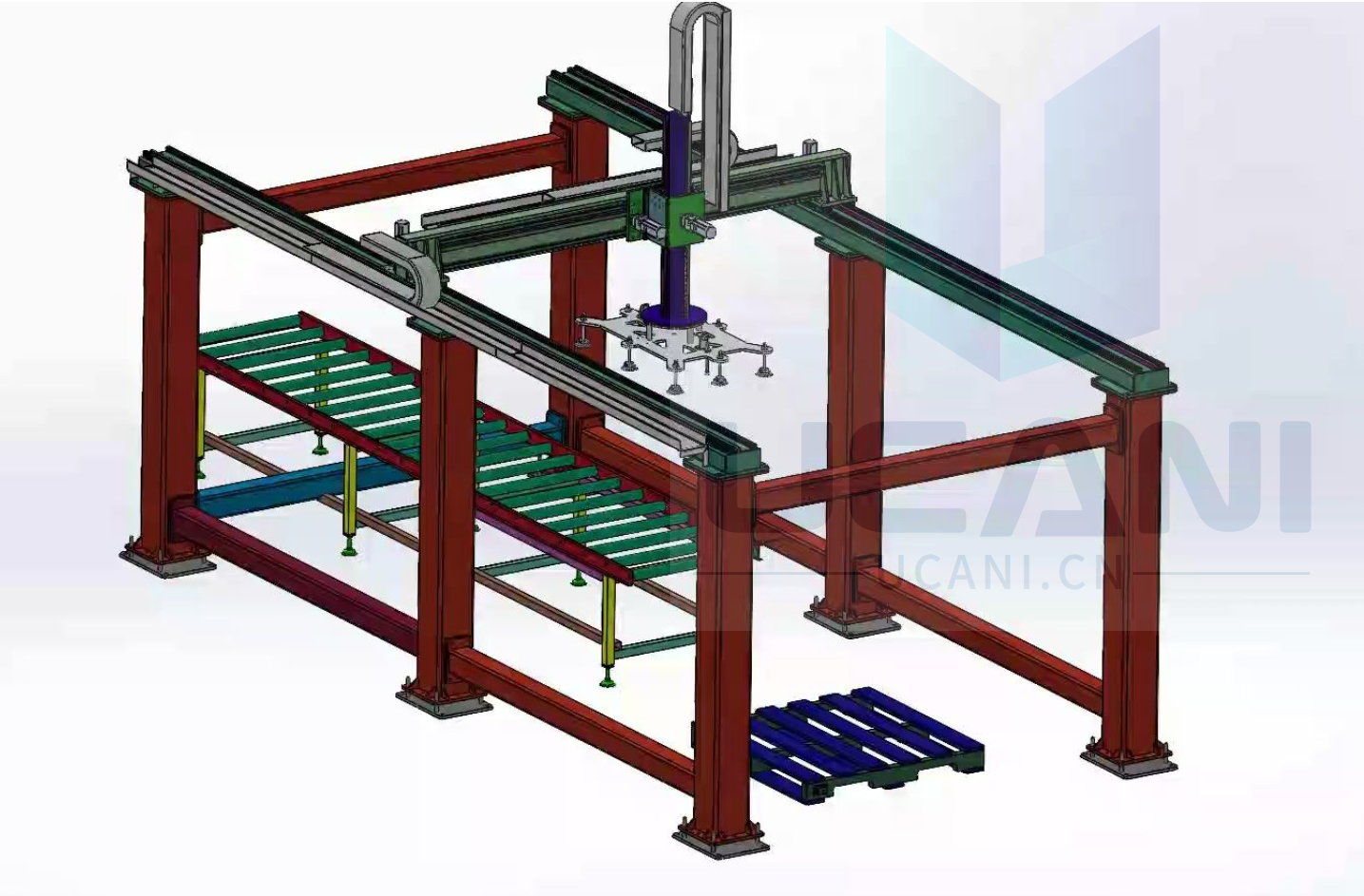

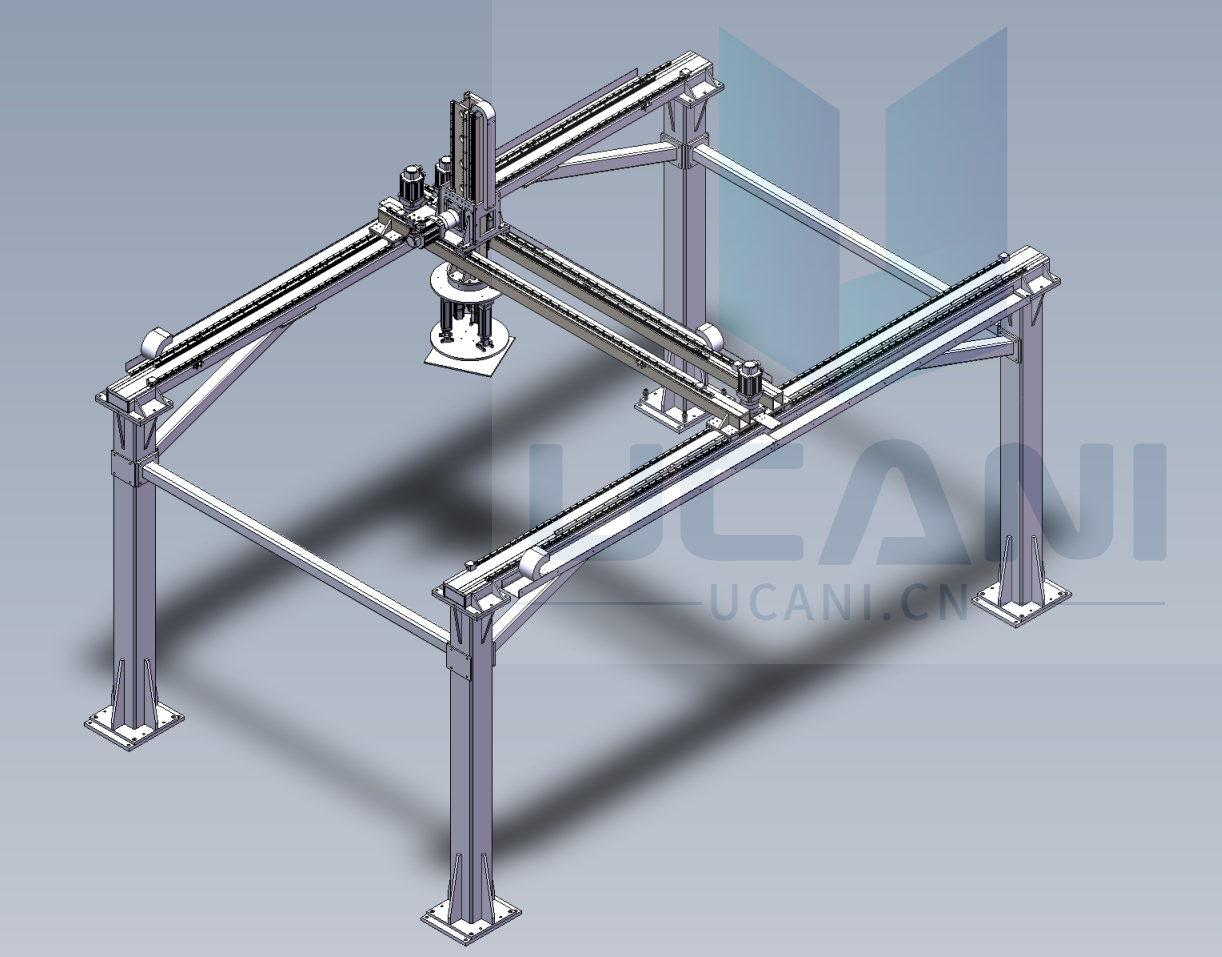

UCANI gantry combination module, heavy-duty sliding platform module, large gantry mechanical mobile phone, human ground rail

UCANI Dragon Gate Combination Module Heavy Duty Sliding Platform Module Large Dragon Gate Mechanical Robot Man Ground Rail, UCANI is a high-tech enterprise that integrates industrial robot research and development and automation equipment production. The company's main products include: linear modules, truss robots, truss manipulators, non-standard customized various robot workstations and automation system integration, UCANI gantry combination modules, heavy-duty sliding platform modules, large gantry mechanical mobile phones, and human ground rails. In practice, automatic loading and unloading machine hands can be widely used in various industries in industrial production, with the advantages of easy operation, high workpiece quality, and so on, At the same time, rescuing operators from heavy and monotonous work environments is increasingly favored by manufacturers. Having this production line is bound to highlight the production strength of enterprises and improve market competitiveness, which is an inevitable trend in industrial production and processing.

UCANI gantry combination module, heavy-duty sliding platform module, large gantry mechanical mobile phone, human ground rail, widely used, can be applied in general automation equipment, for example: automated tin welding machine, locking screw machine, automatic welding machine, laser cutting machine, non-standard equipment material rack parts box picking and placing, small stack, adhesive coating machine, zero accessory picking and handling, CCD lens movement, automatic painting machine, automatic loading and unloading device, cutting machine Electronic component production equipment, small assembly lines, small press tables, spot welding machines, surface coating processes, automatic labeling machines, liquid material filling and packaging, zero accessory inspection equipment, production line workpiece sorting, material filling devices, packaging machines, engraving machines, conveyor belt displacement, workpiece cleaning devices and other automation equipment are applied on machines.

Categories

Latest News

Contact Us

Contact: Gloria

Phone: +8613681981380

Tel: +86 021-64556477

Add: Room 312, Factory Building, No. 338 Shuangbai Road, Minhang District, Shanghai