Delta

ASD-A3 SERIES

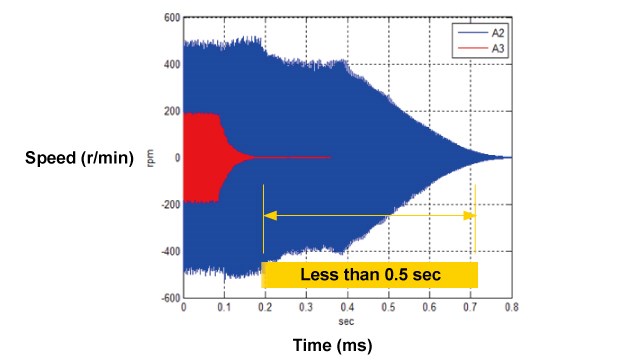

- Product description: Higher responsiveness and shorter settling time increases productivity

As the technology of microprocessor unit becomes more advanced and much further, the development and cost effectivity of permanent magnet manufacturing technology for servo motor and high power and high performance semiconductor power devices is improved continuously. Therefore, AC servo motor and AC servo control system have become the basic techniques for accomplishing automation control technology in current industry field. Delta servo system is an omnibearing integrated servo system which is based on Delta's strength in industrial and electronic technology and developed for different customers' requirements of various application machine tools. All ASDA series servo drives are provided with a superior digital signal processor (DSP) which represents a high-speed performance of the control circuit loop. Besides, the other features of Delta ASDA series, including gain tuning, smooth motor operation and software analysis / monitor function, also provide high-speed and high-precision motion control for a wide range of industrial automation applications.

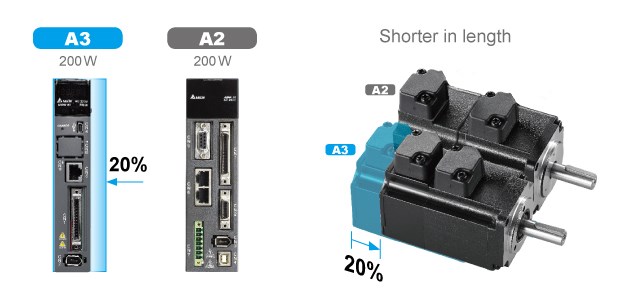

As the market of automated manufacturing rapidly develops, the need for servo products with higher performance, speed, precision, bandwidth, and functionality is widely increasing. To meet the requirements of the motion control market for industrial manufacturing machines, Delta presents a new High-end AC Servo System, the ASDA-A3 Series, with features such as multi-functionality, high-performance, energy-efficiency, and compact design.

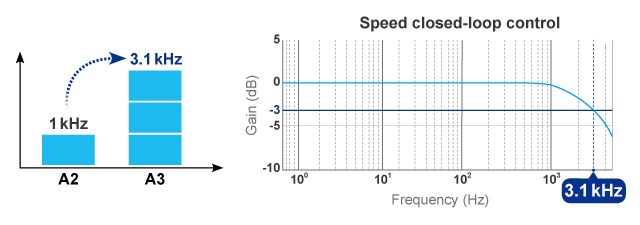

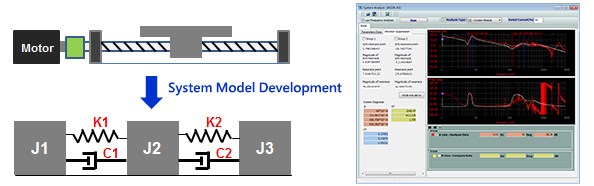

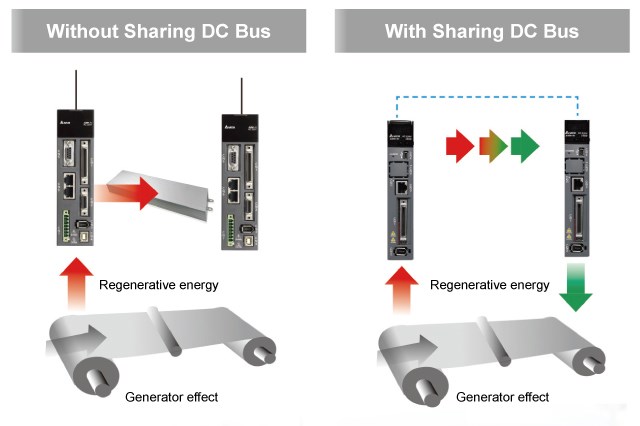

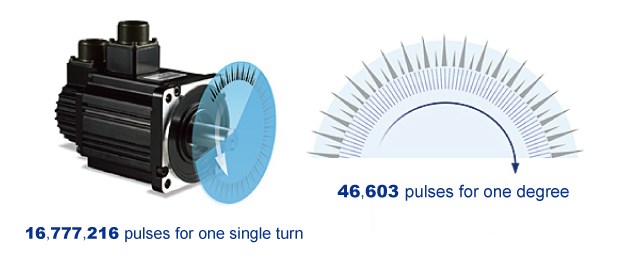

With auto-tuning and a user-friendly interface for system analysis, the ASDA-A3 Series provides 3.1kHz of bandwidth and employs a 24-bit absolute type encoder, creating advantages that include high response, precise locating, and stable and flexible performance. In addition, the series has added new functions such as vibration suppression, system diagnosis, and a shared DC-bus design which can regenerate energy. Delta’s AC Servo System ASDA-A3 Series offers a comprehensive technology and solution to help our customers enhance their machine’s precision and achieve excellent performance.

As the market of automated manufacturing rapidly develops, the need for servo products with higher performance, speed, precision, bandwidth, and functionality is widely increasing. To meet the requirements of the motion control market for industrial manufacturing machines, Delta presents a new High-end AC Servo System, the ASDA-A3 Series, with features such as multi-functionality, high-performance, energy-efficiency, and compact design.

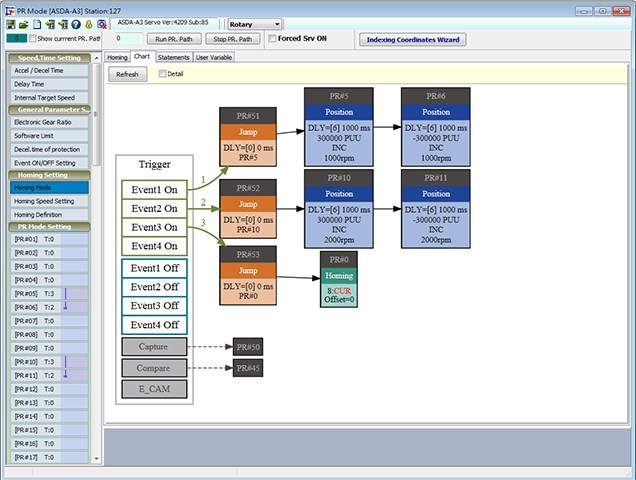

Advanced Motion Control E-CAM & 99 sophisticated motion

- E-CAM & 99 sophisticated motion commands and segments allowed

- Graphical user interface offers simple setup and programming

- Arithmetic operation / comparison commands available

- General motion functions such as homing, position and speed commands

- Superimposition, blending, and jump change motion commands provided

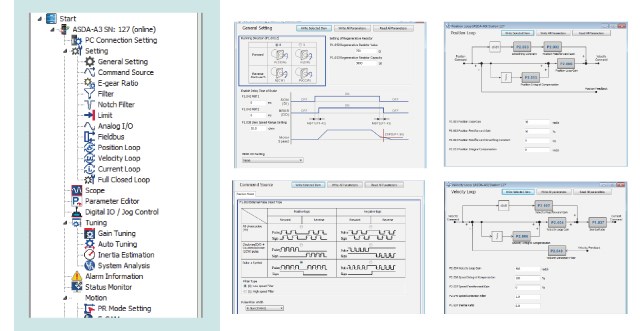

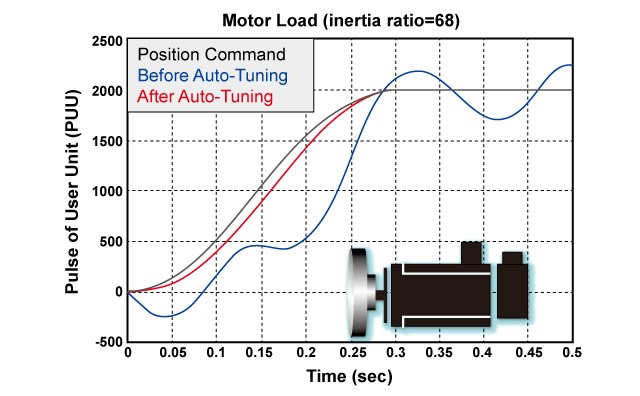

Comprehensive Auto-Tuning Functions

- Built-in auto-tuning function lowers the barriers for users and optimizes machine performance with less tuning effort

- Provides step-by-step guidance wizard for easily tuning and setting up servos via panel keypad or software

Categories

Latest News

Contact Us

Contact: Gloria

Phone: +8613681981380

Tel: +86 021-64556477

Add: Room 312, Factory Building, No. 338 Shuangbai Road, Minhang District, Shanghai